Roof

The roof is one of the structural and esthetic elements that are significant for the whole building. Its shape and the materials used for the finish determine the style of the entire construction; once finished, the roof becomes an element that is expressive of the style of the building.

The roof is the most exposed part of a building and requires regular upkeep. During work to replace it, it is necessary to be watchful to respect the coherence of the whole composition in order not to harm its balance. The use of original materials for a roof replacement contributes to the retention of the architectural integrity of a building.

Québec-style sheet metal

Among the traditional types of metal roofing, that of Quebec-style sheet metal is recognizable for its pattern that looks like a profusion of flat scales. These small lamina are in fact strips of overlapping pieces of sheet metal that are doubled over, and were obliquely nailed on to the overflow of the roof. This technique was worked out in order to solve the problems of imperviousness associated with welded sheets in older arrangements.

Formerly, old tinplate containers were gathered, which were cut and unfolded, to obtain sheets of diverse sizes. Later, materials would be imported from England. Nowadays, more resistant materials such as galvanized or stainless steel sheets as well as pre-painted aluminum sheets are replacing the traditional materials. However, the venerable techniques of installing the sheets have changed very little.

Installation method

(Excerpt from the technical guide no 2, Les couvertures en « tôle à baguettes », collection Maître d'œuvre, Ville de Québec, 1988)

The traditional installation technique consists of installing strips of tin sheets, starting at the lowest part of the sides. They are folded and then tacked on using nails that are driven through the folds. The sheets are then folded back over the nails to form a series of plates whose dimensions vary depending on the size of the sheets.

The contemporary installation technique distinguishes itself from its ancestor in two details. First of all, the strips of sheet metal are now pre-folded in the workshop rather than on the building site in order to allow greater uniformity in the folds and consequently to facilitate the installation. Secondly, metal fasteners that are nailed at the bridging points in order to limit the perforations of the cover now hold the folds in place. In order to counter the galvanic corrosion that results from the use of incompatible metals, it is essential that the fasteners, the complete assembly of the sheet-iron, the hip rafter and the ridge sheathing, as well as the flashings are made of the same metal as the cover.

Church of Sainte-Famille of Cap-Santé

Region: Québec - Chaudière-Appalaches

At this building site, it was a question of whether all the Canadian sheet metal should be replaced, and whether the wooden arrows should be taken down and restored on the ground.

The problems in restoring these roofs arose from their dimensions rather than technical aspects. The type of sheet metal in place was of small dimensions. For the installation, that meant that more rows would have to be laid out, and the greater amount of work would result in higher costs for the building site.

In order to reduce these costs, a type of slightly larger sheet metal was selected. Technically and visually, it was not too much different from the original model in place. By this decision, the expenses of the building site were cut by 20% to 25%.

During the repair of the soffits, major questions arose: at the opening of the base of the roof, at the junction of the masonry walls, significant bulging was noticed. The question consequently arose whether this already expensive building site should not be allowed a second phase for the restoration of the masonry. After several surveys, it proved that the deformations were not recent, and that the walls had since stabilized. One of the principal indices was that the interior decoration, among others that of the cornice, followed the lines of deformation and seemed to be applied to the already deformed wall. This outgrowth of the walls probably dates from the years immediately following the construction of the building.

Sheet metal with rods

Excerpt from the technical guide no 3, Les couvertures en « tôle à baguettes », collection Maître d'œuvre, Ville de Québec, 1988.

"Sheet metal with rods" is a type of metal roofing, which was commonly employed in the 19th century. It was used to cover both important buildings and simple houses. "Sheet metal with rods" is a material of great durability.

This very old technique was probably imported around the year 1800 from Europe. It owes its name to the wooden rods on which the joints of the metal sheets are attached. These wooden cleats, which vary according to the time and the region they were used, are laid out perpendicular on the overflow of the roof, with spacings that depend on the width of the sheets. Thus, the pattern varies according to the shape of the roof. Builders usually used tinplate in the oldest roofs. After 1850, this material was replaced by galvanized sheet metal and, on prestigious buildings, by copper.

There were also similar systems, such as pinched sheet metal or sheet metal with upright joints. One can recognize it by its drawn-up joints, which do not require rods at the longitudinal junction of the sheets. Nowadays, new materials are available, like sheets of stainless steel, of enameled steel, and of pre-painted aluminum. There are also several industrial products, which imitate the pattern of "sheet metal with rods". On the other hand, structures using these materials seldom possess either the aesthetic quality or the degree of strength of the original ones.

Copper

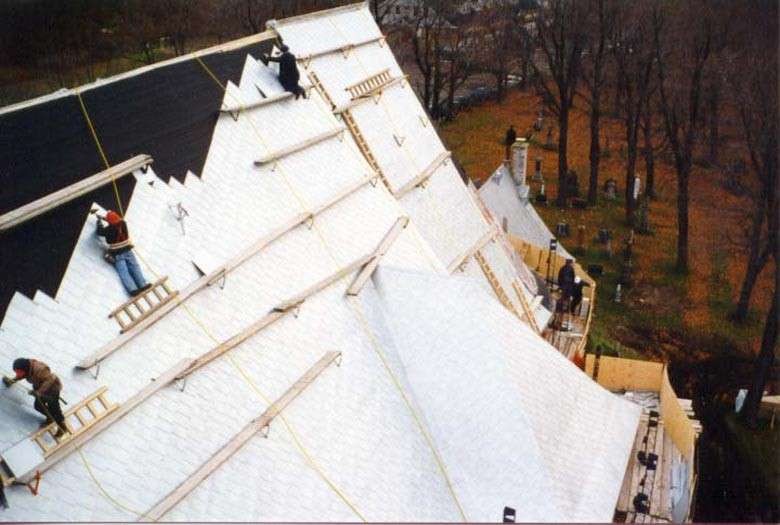

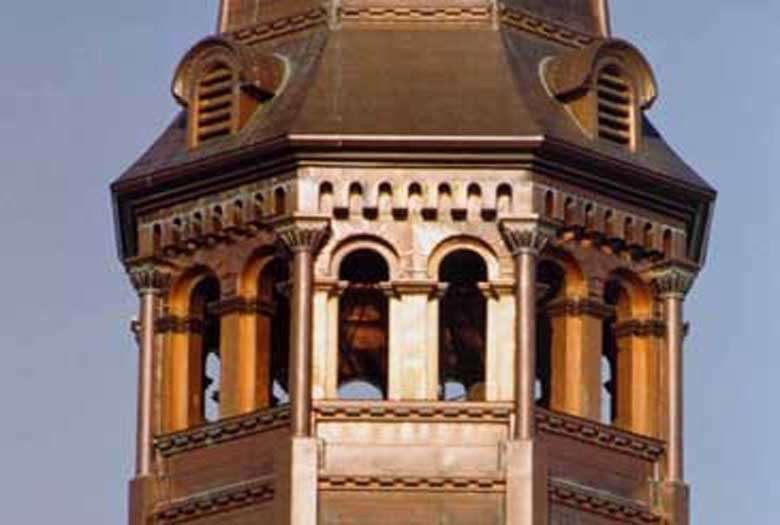

Mother House of the Grey Nuns. Region: Montreal

The work undertaken at the Mother House of the Grey Nuns had the objective to restore the complete structure, and to replace the copper coverings of the spires and of the chapel's bell-tower. Work began in 1997 and was completed 17 months later. The preliminary examination of the structures showed that several sections of the copper had been torn off, damaged or pierced. Moreover, the copper on the bell-tower of the chapel had been painted over on different occasions.

The restoration required that the copper sheets be removed in order to examine the soundness of the underlying wood to avoid all possible structural problems.

The complexity of the construction and the diversity of forms required several hours of preparatory work in a studio to assemble all the modillions of the cornices and to fashion the capitals of columns and other decorative elements. A mobile workshop was installed on the building site to make the folded portions and other necessary adjustments on the spot.

Slate

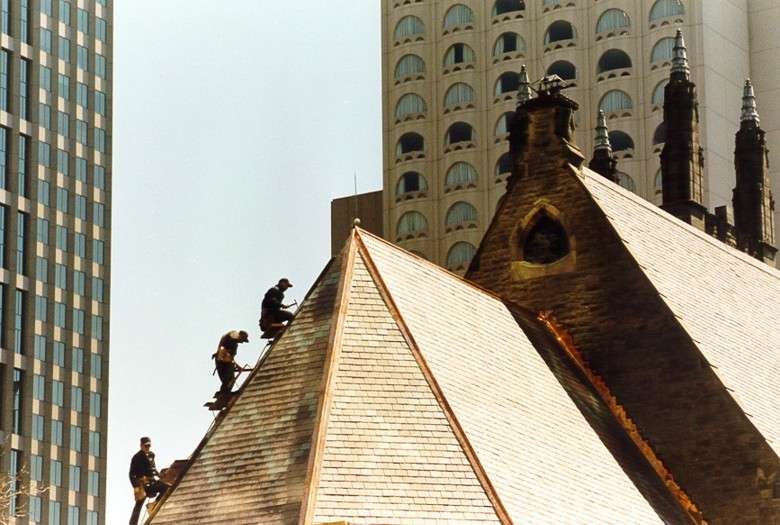

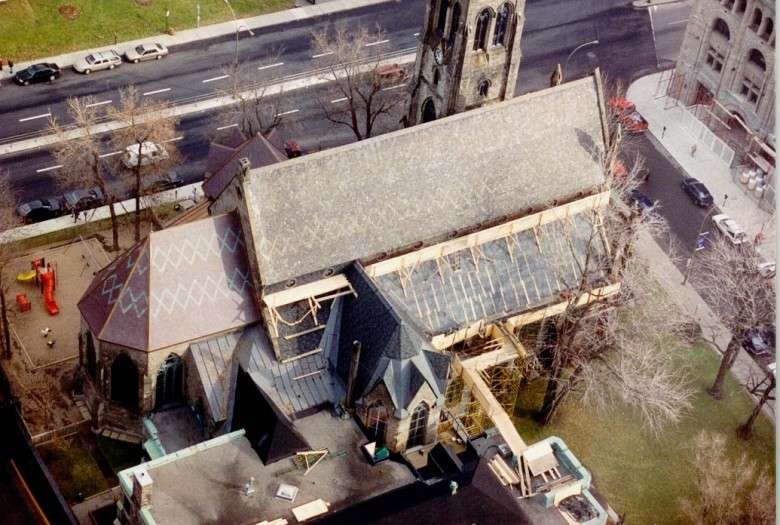

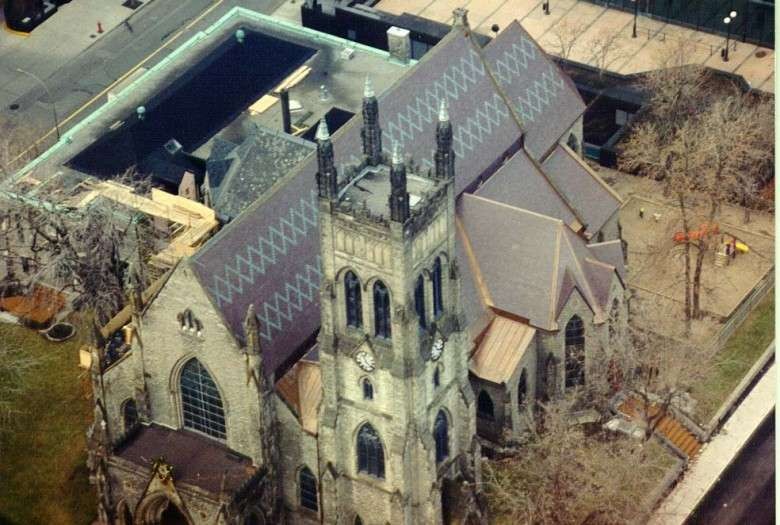

Saint-George's Anglican Church

Region: Montreal

The architect William T. Thomas constructed this church in 1869-1870. Built in a neo-gothic picturesque style, the church was completed with several kinds of stone (sandstone and limestone), which results in a multi-colored appearance of the external walls. One finds this same taste for polychromatic expression in the roof, which amalgamates green and red slate in its geometrical composition.

While slate is a relatively scarce material in Quebec, certain manufacturers and craftsmen have again taken to the production of slate tiles. They answer thus to the growing demand for original materials whenever restorations or renovations are carried out.

While the work was in progress, the firm that was hired installed a small temporary workshop in a park adjacent to the church where it carried out a public demonstration of how the slate is cut.

Any restoration of a roof, in addition to being necessary for the structure of the building, usually generates much interest among the public.